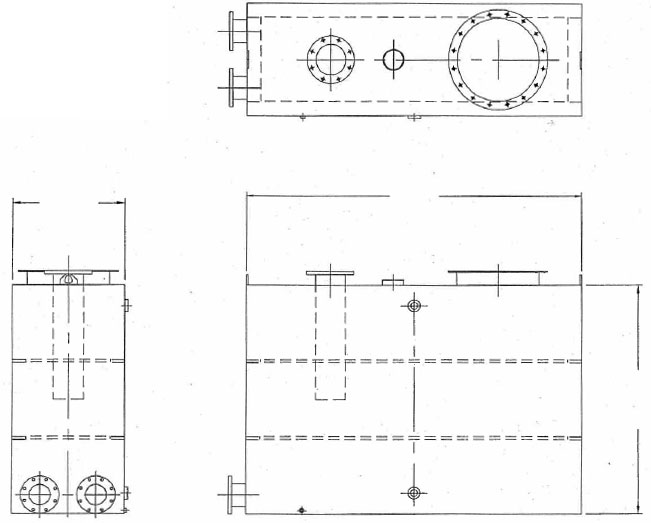

Many cooling tower manufacturers recommend a separate indoor sump tank large enough to fill the entire recirculation system without danger of pump cavitations. As a general rule, the tank should be sized to hold three times the rate of circulation in gallons per minute (gpm). Every tank should have properly sized openings to include: an inlet, outlet, overflow, drain, manhole, water make up, vent and misc. fittings. It is extremely important that the tank is vented properly and does not carry a water column in the vent pipe causing an additional static head pressure on the vessel. If additional head pressure is a possibility, the additional head pressure should be calculated and built into the design of the tank.

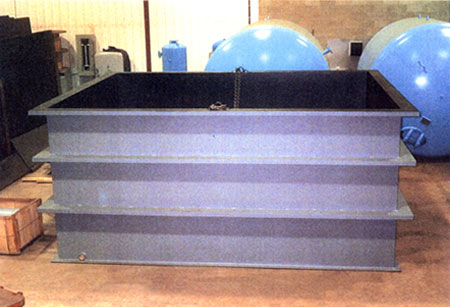

The majority of our cooling tower sump tanks are sandblasted interior to a near white, followed by 7 to 11 mils DFT of epoxy. If the tank has a flat bottom, the exterior bottom of the tank should have a commercial blast followed by a coal tar epoxy, to protect from the condensation. The alternative is that the bottom is supported on a structural skid to get the tank off the floor. Midwest Tank Co. recommends the side wall and top to have a commercial blast followed by a universal primer as a minimum. Finish coating is available.

Options inside the vessel include: an anti-vortex on the suction side, interior baffle, and internal screen.

Note: Rectangular tanks made of steel and epoxy lined require structural support on the outside of the tank. Lined tanks require all welds to be continuous, therefore; interior structural support becomes costly. Stainless steel rectangular tanks may have the structural support on the inside of the tank with staggered fillet welds.

Note: The capacity you require or mark the diameter and Height

Interior: Epoxy Lined

Exterior: Shop Primed

| Specifications | |

|---|---|

| Interior | Epoxy Lined |

| Exterior | Shop Primed |