Your Guide for Pressure Vessels

All of our air receivers are built to ASME Code, Section VIII, Division 1, and are labeled with the U stamp. Each tank is registered with the National Board and has a National Board Number. Midwest tanks are accepted in all 50 states.

All of our air receivers are built to ASME Code, Section VIII, Division 1, and are labeled with the U stamp. Each tank is registered with the National Board and has a National Board Number. Midwest tanks are accepted in all 50 states.

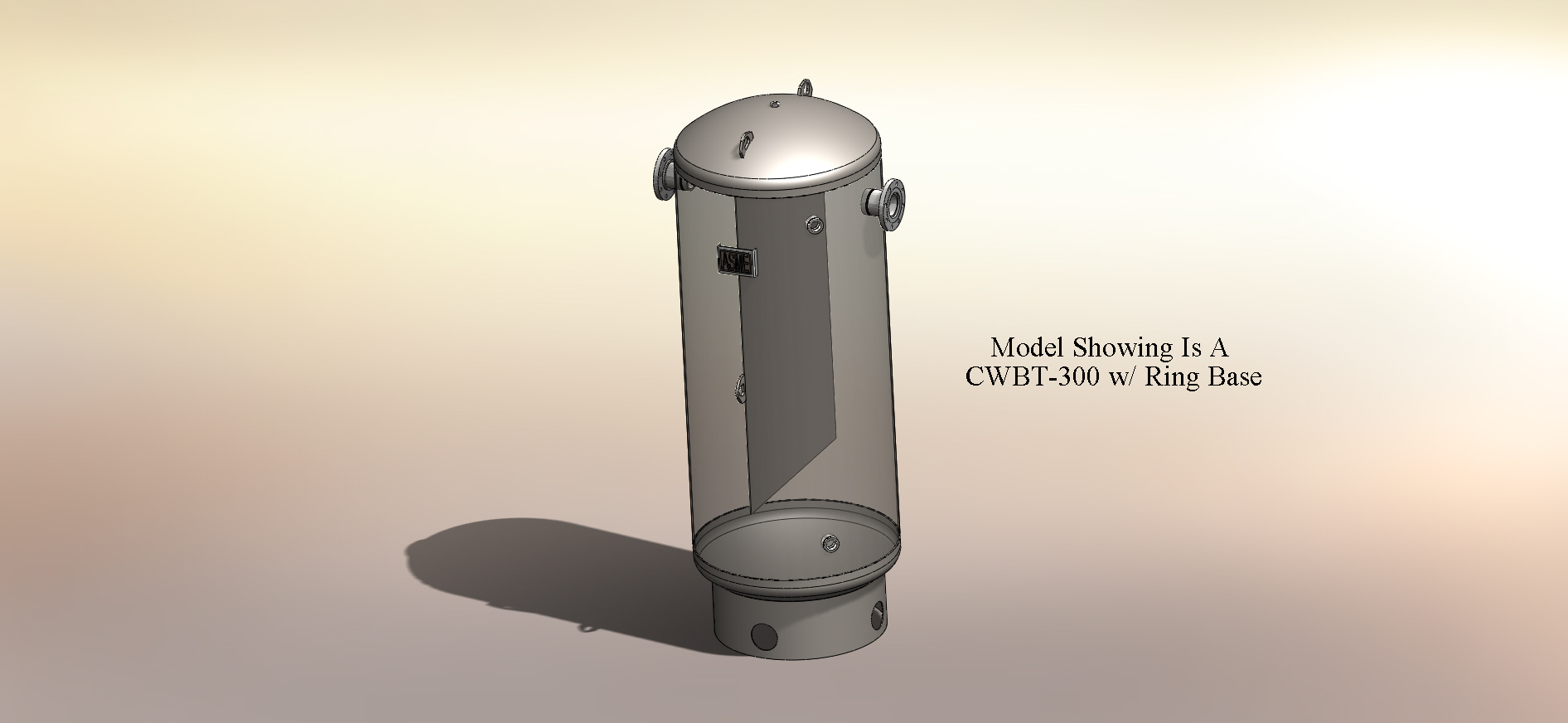

Midwest Tank has been producing quality hot water storage tanks since 1972. We offer a variety of sizes, linings, heating coils, and working pressures.

Manufactured in accordance with section VIII, ASME pressure vessel code. Fitting locations to be dimensioned from head and shell joint.

12 x 16 Manway Standards only on cement, phenolic lined, and all tanks 42″ diameter and over. All others to have inspection openings as required by ASME code.

Manufactured in accordance with section VIII, ASME pressure vessel code. Fitting locations to be dimensioned from head and shell joint.

12 x 16 Manway Standards only on cement, phenolic lined, and all tanks 42″ diameter and over. All others to have inspection openings as required by ASME code.

Midwest Tank Co. standard tappings for pressure tanks used in hydropneumatic service. The standard interior lining for hydropneumatic tanks is a TNEMEC Series 20-2000 Pota-Pox with a 7 to 11 mil DFT. This is an NSF approved coating and is used throughout the industry for protection in cold water applications.

Whether it is a gravity tank, suction tank, or pressure vessel, Midwest Tank can build a sprinkler storage tank to meet your job specification.