Your Guide For Hydropneumatic Tanks

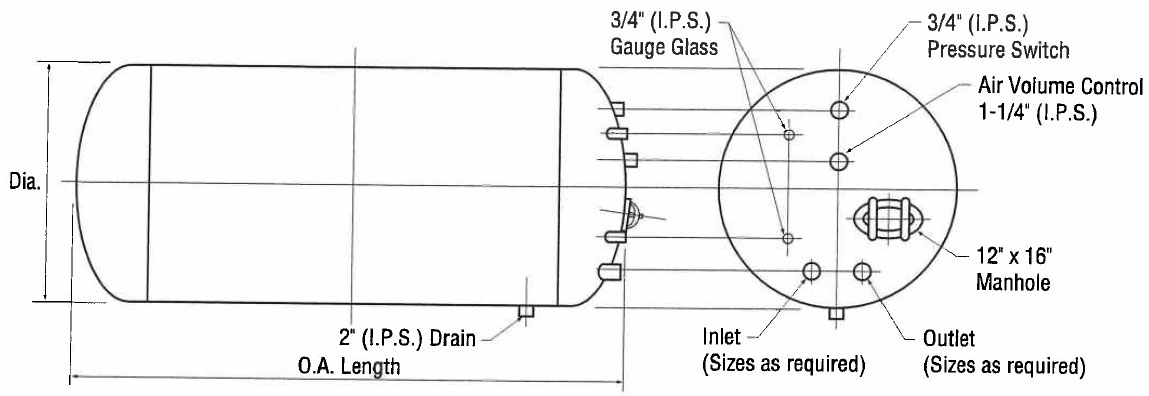

Midwest Tank Co. manufactures hydropneumatics storage tanks to maintain on-demand pressurized water without the continuous use of a pump. By regulating system pressures, hydropneumatics tanks provide efficient water supply to quickly meet system demand. Our standard interior lining for hydropneumatic tanks is a TNEMEC Series 21 epoxy. This is an NSF approved coating and is used throughout the industry for protection in cold water applications. This coating requires an SSPC-SP 10 near-white blast. All tank exteriors shall be primed. Alternate linings and coatings are available. All tanks are ASME labeled and are available in 100, 125, and 150 PSI design pressures.

We custom build our Hydropneumatic tanks to meet your job requirements. See below for some of our more common sizes.

How Hydropneumatic Tanks Work

Hydropneumatic tanks regulate water pressure by storing water and compressed air in the same vessel. As water is drawn from the system, the air pressure inside the tank helps push water into the piping network, maintaining consistent pressure without the pump needing to run continuously. This setup reduces pump cycling, prevents water hammer, and improves the overall efficiency and lifespan of your water system.

| Item # | Capacity | Diameter | Overall Height |

|---|---|---|---|

| HP4854 | 513 gal | 48 in | 78 in |

| HP4860 | 560 gal | 48 in | 84 in |

| HP4872 | 654 gal | 48 in | 96 in |

| HP4884 | 748 gal | 48 in | 108 in |

| HP4896 | 842 gal | 48 in | 120 in |

| HP48120 | 1030 gal | 48 in | 144 in |

| HP48144 | 1218 gal | 48 in | 168 in |

| HP48168 | 1406 gal | 48 in | 192 in |

| HP5460 | 712 gal | 54 in | 87 in |

| HP5472 | 840 gal | 54 in | 99 in |

| HP5484 | 959 gal | 54 in | 111 in |

| HP5496 | 1078 gal | 54 in | 123 in |

| HP54120 | 1316 gal | 54 in | 147 in |

| HP54144 | 1554 gal | 54 in | 171 in |

| HP54168 | 1792 gal | 54 in | 195 in |

| HP6060 | 912 gal | 60 in | 90 in |

| HP6072 | 1059 gal | 60 in | 102 in |

| HP6084 | 1206 gal | 60 in | 114 in |

| HP6096 | 1353 gal | 60 in | 126 in |

| HP60120 | 1647 gal | 60 in | 150 in |

| HP60144 | 1941 gal | 60 in | 174 in |

| HP60168 | 2235 gal | 60 in | 198 in |

| HP6660 | 1134 gal | 66 in | 88 in |

| HP6672 | 1312 gal | 66 in | 100 in |

| HP6684 | 1490 gal | 66 in | 112 in |

| HP6696 | 1668 gal | 66 in | 124 in |

| HP66120 | 2023 gal | 66 in | 148 in |

| HP66144 | 2379 gal | 66 in | 172 in |

| HP66168 | 2735 gal | 66 in | 196 in |

| HP66192 | 3091 gal | 66 in | 220 in |

| HP7260 | 1439 gal | 72 in | 96 in |

| HP7272 | 1651 gal | 72 in | 108 in |

| HP7284 | 1863 gal | 72 in | 120 in |

| HP7296 | 2075 gal | 72 in | 132 in |

| HP72120 | 2499 gal | 72 in | 156 in |

| HP72144 | 2932 gal | 72 in | 180 in |

| HP72168 | 3344 gal | 72 in | 204 in |

| HP72192 | 3767 gal | 72 in | 228 in |

| HP72216 | 4190 gal | 72 in | 252 in |

| HP72240 | 4613 gal | 72 in | 276 in |

| HP72264 | 5036 gal | 72 in | 300 in |

| HP72288 | 5460 gal | 72 in | 324 in |

| HP7896 | 2613 gal | 78 in | 140 in |

| HP78144 | 3609 gal | 78 in | 188 in |

| HP78192 | 1604 gal | 78 in | 236 in |

| HP8496 | 3070 gal | 84 in | 143 in |

| HP84144 | 4222 gal | 84 in | 191 in |

| HP84192 | 5373 gal | 84 in | 239 in |

| HP84288 | 7676 gal | 84 in | 335 in |

| HP9096 | 3579 gal | 90 in | 146 in |

| HP90192 | 6223 gal | 90 in | 242 in |

| HP90288 | 8867 gal | 90 in | 338 in |

| HP90384 | 11510 gal | 90 in | 434 in |

Advantages of Using a Hydropneumatic Tank

A properly designed hydropneumatic tank provides multiple operational and cost-saving benefits:

- Reduced Pump Wear –Limits the frequency of pump starts and stops, extending equipment life.

- Stable System Pressure – Minimizes pressure fluctuations to protect sensitive equipment and piping.

- Energy Efficiency – Decreases energy use by reducing unnecessary pump operation.

- Improved Water Supply Response – Ensures water is available instantly when demand peaks.

- Flexible Design – Can be tailored to fit municipal, commercial, or industrial water systems.

Industries & Applications

Hydropneumatic tanks are essential wherever consistent water pressure and reliable supply are needed. Midwest Tank Company builds tanks for:

- Municipal Water Systems –Ensuring steady pressure for residential and commercial distribution.

- Commercial Buildings – Supporting high-demand plumbing systems in hotels, hospitals, and office complexes.

- Industrial Facilities – Providing reliable water supply for process cooling, manufacturing, or fire suppression.

- Irrigation & Agriculture – Delivering consistent pressure for crop watering systems and livestock operations.

FAQs

What is a Hydropneumatic Tank?

A hydropneumatic tank is a pressurized water storage vessel that uses compressed air to maintain consistent water pressure in a distribution system. It prevents pumps from running continuously by storing both water and air in a controlled environment.

What Coatings are Used Inside Hydropneumatic Tanks?

Midwest Tank Company’s standard interior lining is TNEMEC Series 21 epoxy, an NSF-approved coating ideal for cold water applications. Alternative linings and coatings are available based on water chemistry and environmental requirements.

How Do I Size a Hydropneumatic Tank?

Tank sizing depends on pump capacity, desired pressure range, water demand, and system layout.

Ready to Design Your Hydropneumatic Tank?

Whether you need a standard-size vessel or a fully customized hydropneumatic tank built to your specifications. Midwest Tank Company delivers quality ASME-certified and will provide a detailed drawing for approval before production.

Contact our team today to discuss your project, request a quote, or submit your system specifications. We’ll help you get the right hydropneumatic tank to keep your water system running efficiently and safely.